Projects

Degree Thesis

- Temperature Monitoring for Laser-based Directed Energy Deposition Process

Zhaolin Wei (Supervisor: Ryozo Nagamune & Xiaoliang Jin).

Control Engineering Laboratory (CEL) & Advanced Manufacturing Processes Laboratory (AMP)

Investigated and implemented a closed-loop temperature monitoring system for Laser-based Directed Energy Deposition (L-DED). Developed a thermal control strategy to stabilize the melt pool temperature, ensuring consistent material deposition and reducing defects in additive manufacturing processes.

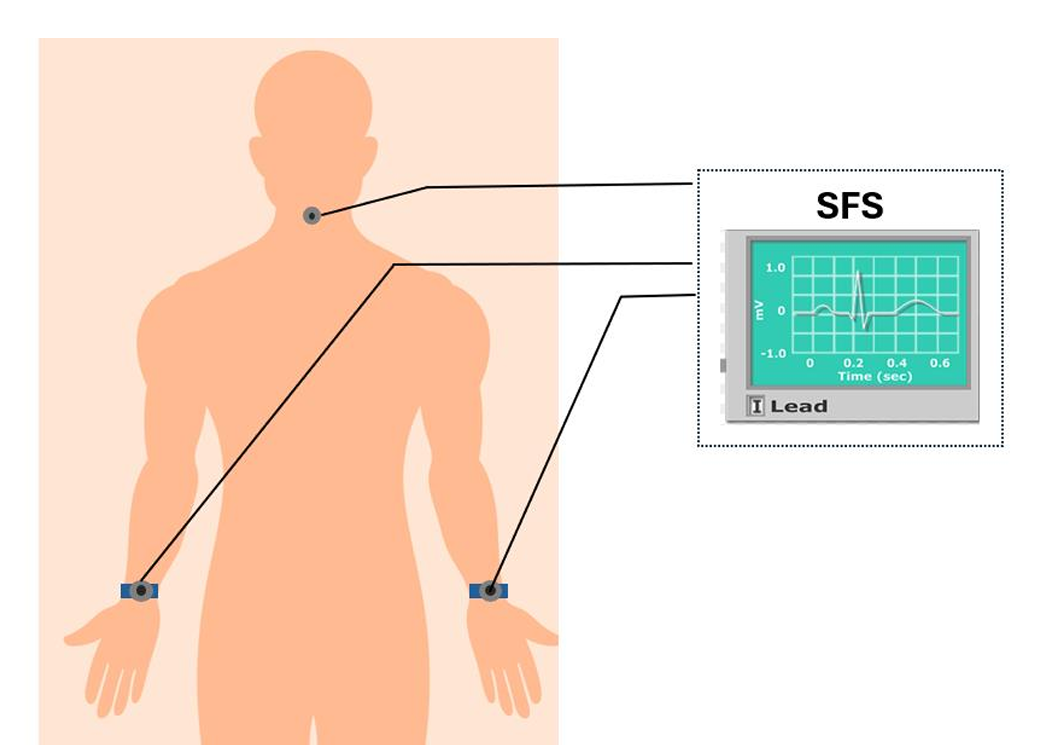

- Self-powered Flexible Electromechanical Sensors for Personal Health Evaluation

Zhaolin Wei (Supervisor: Junwen Zhong).

Soft Sensors-Actuators-Robots Laboratory 柔性傳感器-執行器-機器人實驗室

Developed novel self-powered flexible sensors capable of detecting subtle physiological signals (such as pulse and muscle movements) for personal health monitoring. The project focused on material synthesis, electromechanical characterization, and the integration of sensors into wearable devices.

Projects

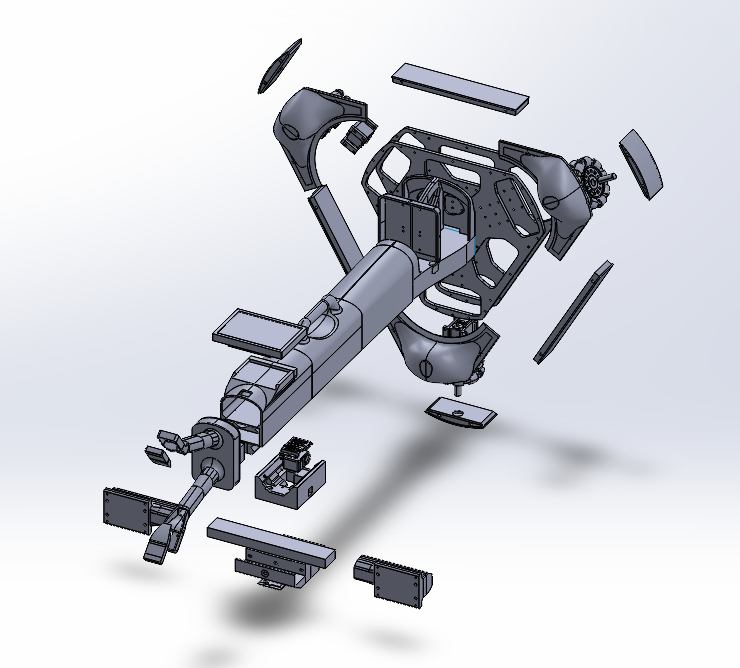

- [in progress] Low-Cost Dual-Arm Mobile Robot Platform (AlohaMini)

Currently building a low-cost, teleoperated dual-arm mobile manipulator based on the open-source framework. The project involves full hardware integration, actuator control implementation, and data collection to validate imitation learning algorithms for household automation tasks.

-

Simulation and Control Optimization of BLDC Motor Drive Systems

Academic Project, Electric Power and Energy Systems Group

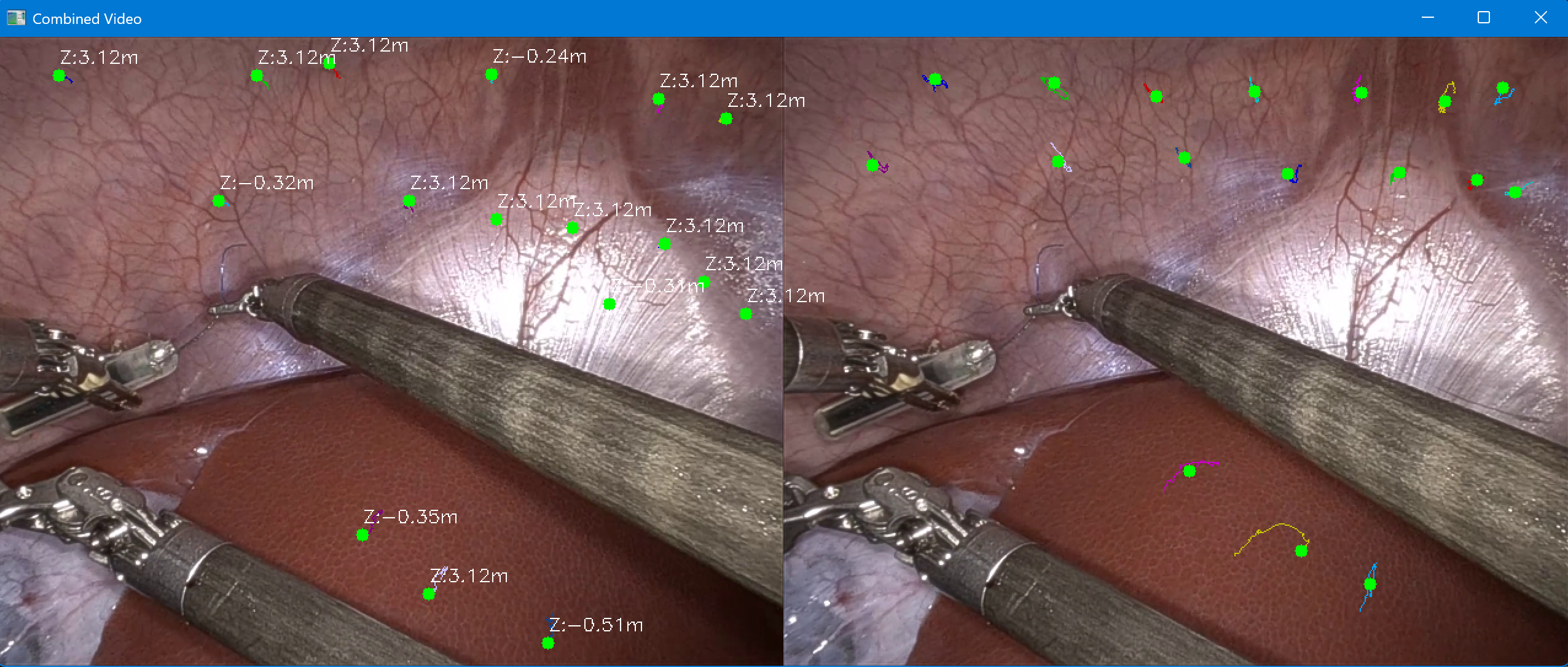

Developed a dynamic simulation model for Brushless DC (BLDC) motor drives using MATLAB/Simulink, incorporating Average Value Models (AVM) to significantly optimize computational efficiency. Designed and implemented a Maximum Torque Per Voltage (MTPV) control strategy by mathematically formulating the optimal voltage lead angle, maximizing high-speed torque output under voltage constraints. - 3D Surgical Instrument and Tissue Tracking System

Academic Project

Built a real-time stereo vision tracking system using Python and OpenCV to capture 3D trajectories of surgical instruments and soft tissue. Integrated Lucas-Kanade optical flow with Shi-Tomasi corner detection and optimized pyramid layers, reducing tracking failure rates by 15% during rapid movements and achieving sub-pixel tracking accuracy (<0.8 pixels).

-

Electromagnetic Calculation Program for DC Permanent Magnet Motors

Developed a Python-based computational tool to analyze the electromagnetic properties of DC permanent magnet motors. The program automates magnetic circuit calculations to predict motor performance, reducing the reliance on manual iterations and facilitating rapid preliminary design optimization.

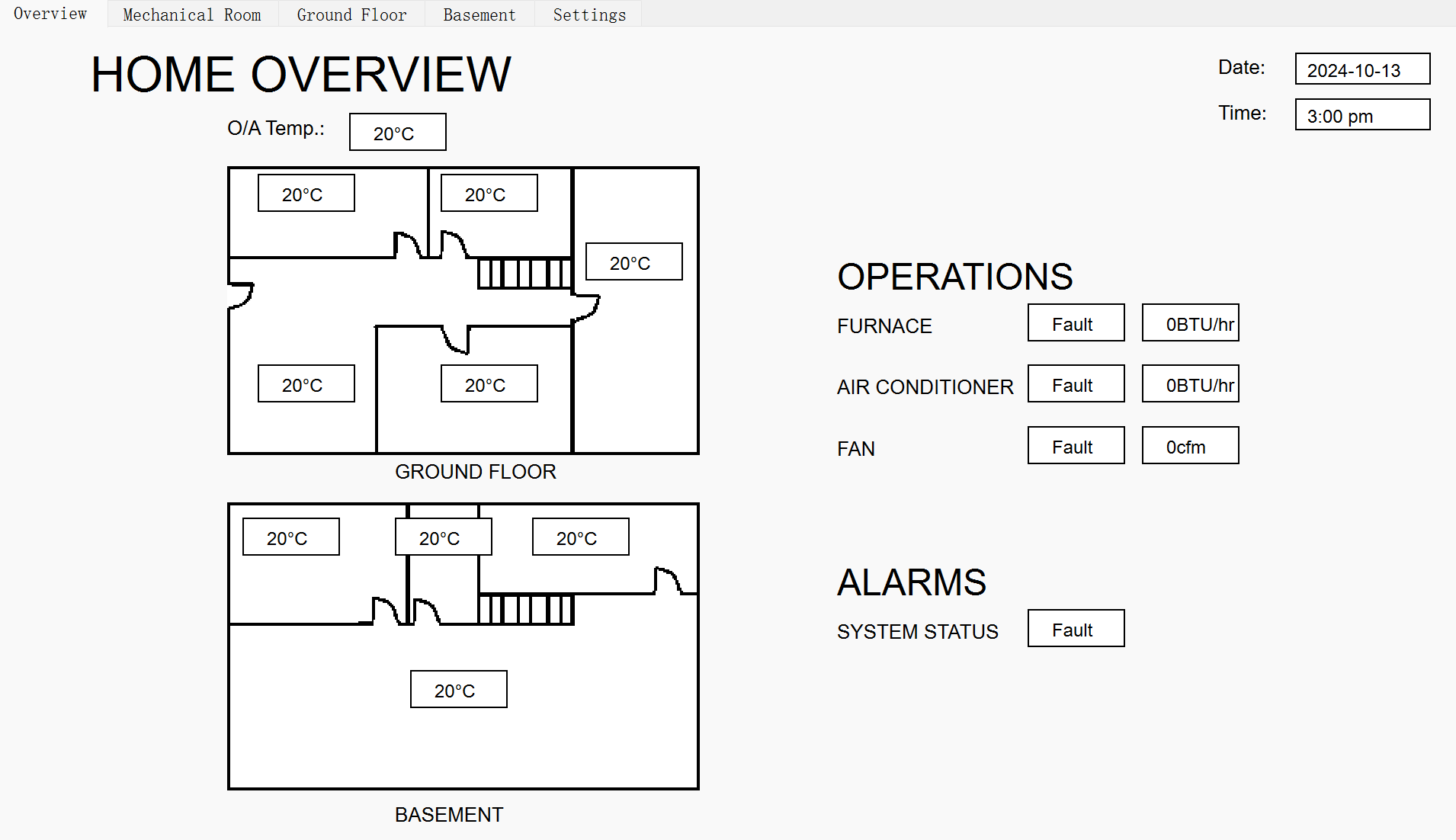

- An Autonomous System for a Room HVAC system

Intern Project, Sands China.

Designed an autonomous automation system for home HVAC systems, featuring an interactive GUI for monitoring and controlling HVAC components dynamically. The system optimized energy consumption while maintaining user comfort through real-time feedback loops.

-

Automated Warehouse Management System

Course design, UBC

Engineered a sophisticated simulation platform for warehouse operations management. It provides a two-dimensional environment where users can define warehouse parameters, manage items and robots, and execute automated tasks through an intuitive graphical interface. -

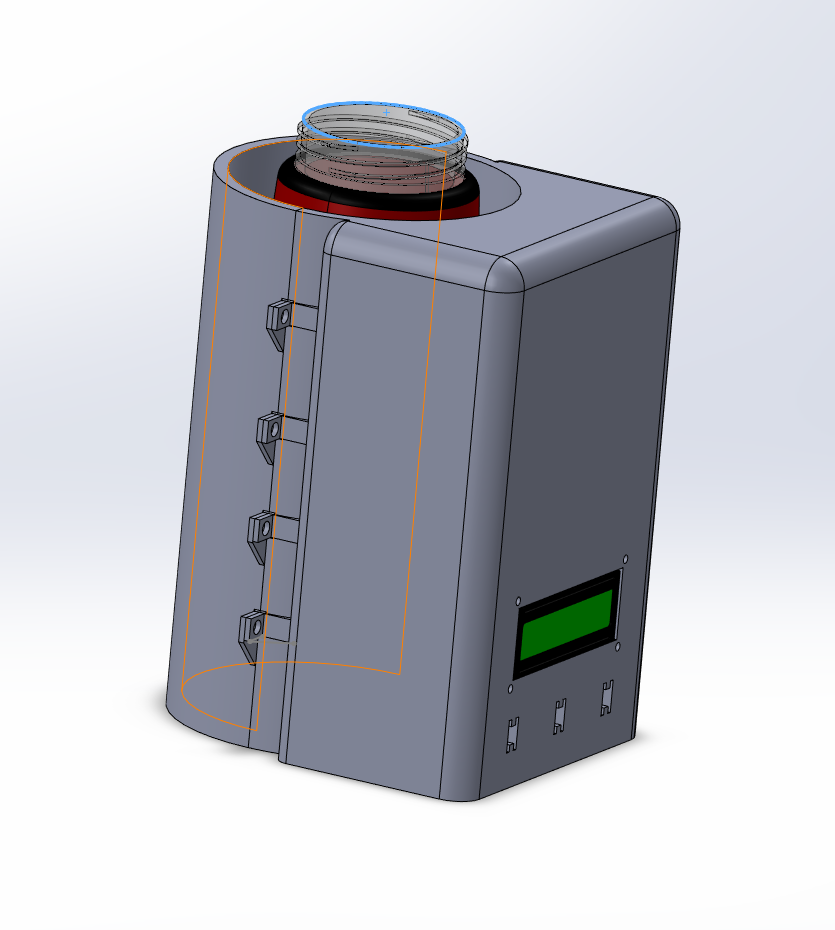

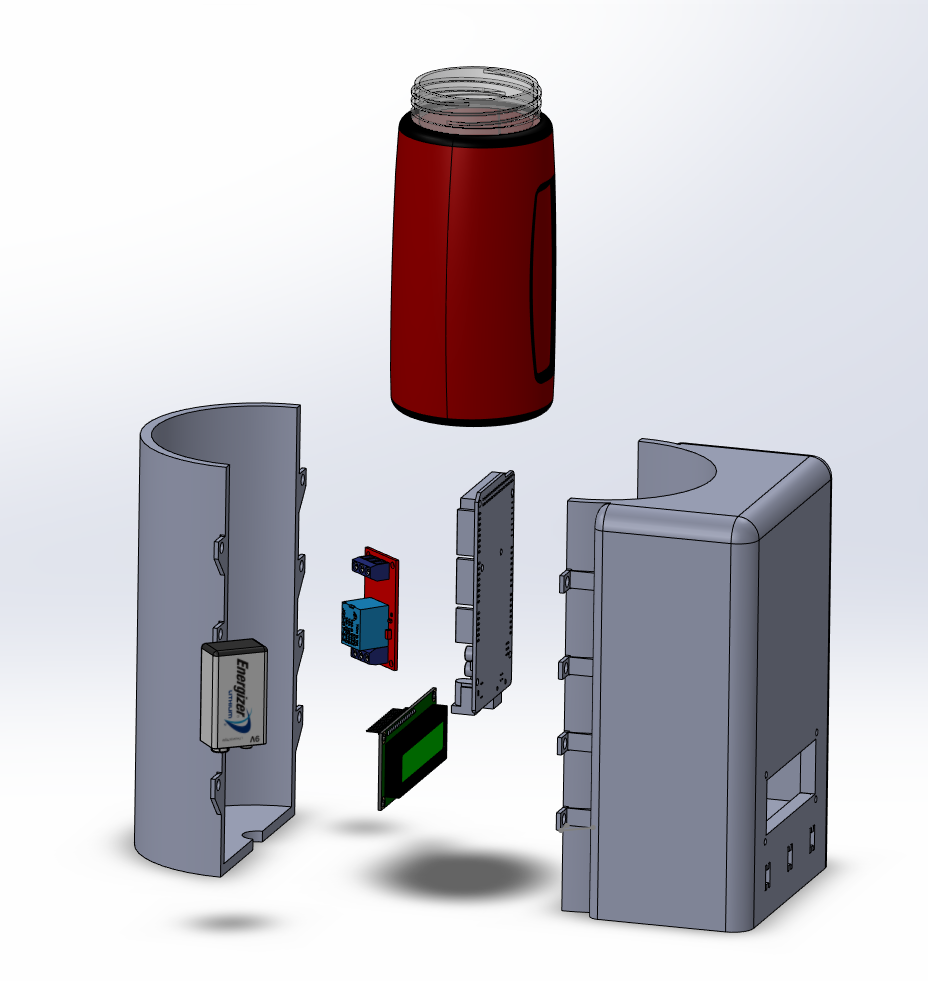

Arduino-Based Smart Cup Heater

Built an Arduino-controlled cup heater with a user-selectable setpoint between 10–80°C via a button interface and real-time LCD readout. Calibrated the temperature sensor to correct measurement offset versus actual water temperature and refined the control code, achieving accurate heating to the desired temperature with clear on-device feedback.

- Old-fashioned Sewing Machine Solidworks Model

Course design.

Modeled a fully functional vintage sewing machine assembly (50+ components) in SolidWorks. Performed comprehensive tolerance stack-up analysis and applied GD&T standards (ASME Y14.5) to ensure kinematic accuracy and manufacturability of the complex mechanical linkages.